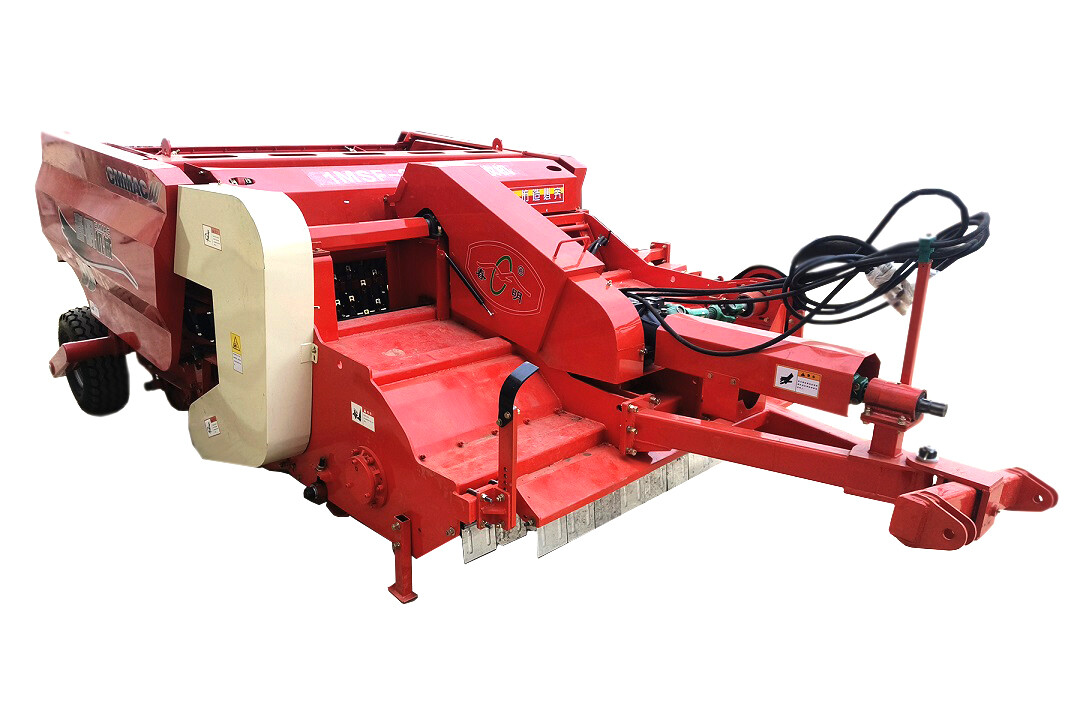

Residual Film Recovery Machine

Since most agricultural waste consists of plastic products that are not easily degradable, long-term accumulation in fields can disrupt normal agricultural production. In some areas, this has severely impacted farming activities and is referred to as "white pollution." Therefore, our company has developed the Residual Film Recovery Machine, which has become the most effective equipment for eliminating and mitigating "white pollution." This machine is specifically designed for normal agricultural use, intended solely for residual film recovery operations. It integrates straw crushing and field return, debris separation, residual film collection, and residual film baling into one innovative system. Any other usage is considered inconsistent with its intended purpose.

Product Structural Features

This machine adopts150~240 horsepower wheeled tractor traction with a hitch connection, ensuring easy and quick installation. It can simultaneously complete straw crushing and field return as well as residual film recovery and baling operations, reducing the number of machine passes and operational costs while shortening working time. The flail-type straw crushing mechanism delivers excellent crushing results with minimal soil damage, improving pickup efficiency and residual film sorting. The spiked belt pickup mechanism ensures full-width collection, high residual film recovery rates, and clean pickup. The double-lying film-impurity separation and mixing device achieves effective separation with low straw and soil content in the collected film. The plate-and-leaf-wheel impurity removal device provides excellent impurity removal with low residual film entanglement. The belt-type residual film compression and baling device ensures compact packaging, and the automatic hydraulic film unloading is convenient and efficient, enabling on-site film unloading to reduce transportation time and costs. The hydraulic lift-type walking wheels are simple and easy to operate, with excellent terrain adaptability, low ground pressure, and high suitability for sandy soils. The machine features a simple structure, convenient maintenance, reliable operation, and is suitable for various field conditions.

Main Technical Parameters